Production Process

Production Process

Each stage of our production process, from materials preparation to glazing, undergoes strict quality control to ensure precision, durability, and compliance with international standards.

Materials Preparation : Raw aluminium profiles and panels are carefully cut, cleaned, and prepared to ensure accurate dimensions and superior quality. Each material is inspected to meet design and performance requirements before entering fabrication.

Fabrication : Aluminium profiles and connectors are assembled to create the main structural framework. Every joint and connection is fabricated with precision to ensure long-term stability, strength, and reliability of the façade system.

Assembly : All fabricated components are integrated with accessories such as brackets, joints, and reinforcement parts to form a complete system. Each unit is fine-tuned and pre-assembled for accuracy and easy on-site installation.

Glazing : Glass panels or other infill materials are installed into the aluminium frames with gaskets and sealants for watertightness, insulation, and aesthetic consistency. The glazing process ensures both performance and visual perfection before delivery.

Every completed unit is then carefully packed and prepared for transportation to site.

Aluminium Materials Physical Check

To ensure long-lasting quality and consistency, every aluminium component is physically tested before installation. Our inspection process follows international standards and focuses on three key parameters:

-

Coating Thickness TestingMeasures the thickness of powder coating or anodizing to verify compliance with AAMA and ASTM standards, ensuring long-term durability and color stability.

-

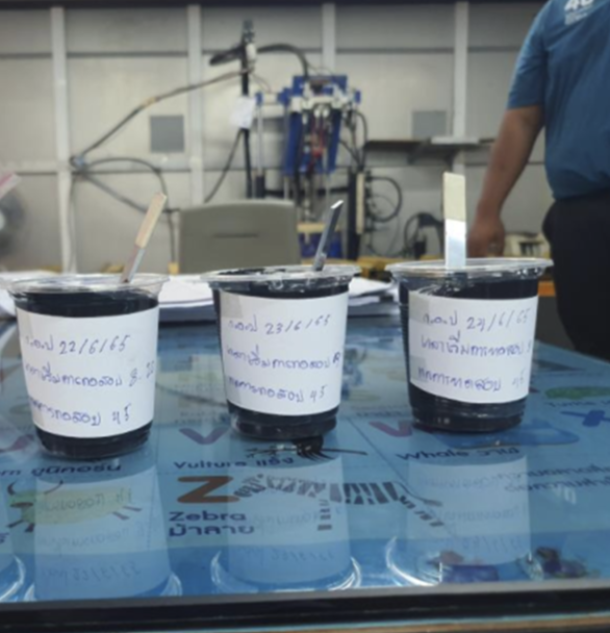

Delta E TestingEvaluates color deviation (ΔE) between samples to maintain visual uniformity across all façade elements.

-

Cross Cut TestingChecks coating adhesion by precisely cutting and peeling the surface to confirm proper bonding between the aluminium substrate and coating layer.

These quality control procedures guarantee that every product delivered meets both performance and aesthetic expectations.

Glass Materials Physical Check

All glass materials undergo a strict inspection process to ensure clarity, safety, and compliance with international façade standards. Each panel is carefully examined through the following tests:

Scratches Checking

Each glass panel is inspected under backlight conditions to detect surface scratches, edge defects, or visual distortions that could affect façade appearance.

Low-E Coating Checking

Verifies the presence and orientation of Low-E coating using a digital meter to ensure the correct reflective side is installed, optimizing energy efficiency and performance.

Roller Wave Checking

Measures the flatness of tempered glass by evaluating roller wave distortion to ensure optical quality, especially for high-performance façades or large glass panels.

Every component fabricated in our workshop undergoes a rigorous Quality Control

(QC) process to ensure precision and compliance with design intent. Our QC team checks each item before assembly and delivery to site based on four key aspects:

-

Dimensional AccuracyEach aluminium and glass component is measured precisely according to approved shop drawings to ensure proper fitting and seamless façade alignment.

-

Connection Quality CheckAll mechanical joints, brackets, and fixings are inspected to ensure structural integrity and load-bearing performance.

-

Compliance with Design SpecificationEvery fabricated unit is verified against design drawings, system details, and client specifications for accuracy and completeness.

-

Check Material UsageMaterial usage reports are reviewed to ensure the correct profile, thickness, and coating type are used for each element.

Through this systematic inspection process, we guarantee that every façade component fabricated in our facility meets the highest standards of performance, safety, and visual quality before site installation.

Ready to Transportation

Each completed façade panel and aluminium component is systematically packed and arranged for safe and efficient delivery to the project site.

Every unit is clearly labeled and tagged with a unique panel number, matching the master layout drawing. This ensures seamless coordination during installation — enabling the site team to identify, track, and assemble each panel accurately and efficiently.

All materials are loaded on customized transport racks to prevent damage during handling and transit, maintaining the high-quality condition of every component from factory to façade.

-

Dimensional AccuracyEach aluminium and glass component is measured precisely according to approved shop drawings to ensure proper fitting and seamless façade alignment.

-

Connection Quality CheckAll mechanical joints, brackets, and fixings are inspected to ensure structural integrity and load-bearing performance.

-

Compliance with Design SpecificationEvery fabricated unit is verified against design drawings, system details, and client specifications for accuracy and completeness.

-

Check Material UsageMaterial usage reports are reviewed to ensure the correct profile, thickness, and coating type are used for each element.